This blog is an overview of how HyperShock handles logistics. We’ll discuss how we handle shipping and our pit space. As team quartermaster, I spend a lot of time planning our shipping and unpacking. I like to experiment with layouts and kits in our shop to see what makes certain tasks easier. There are a couple of toolboxes that contain everything we need to work on certain assemblies which can then be packed up so those items don’t get mixed back into the rest of the pit.

[Arrival Day]

Shipping to BattleBots is the second most critical date after the start of filming. Typically, domestic crates are picked up about 10 days before the start of filming. International crates are picked up a week or so earlier. Most teams ship in one large crate, some use a combination of pallets and crates. BattleBots covers the cost of shipping, which also means they control the means of shipping. While we’re more or less free to use any crate or container, we have to ship on their schedule. They need the majority of the crates at the venue early enough to get them all sorted into teams’ pits. Many of the teams that can drive to the venue take full advantage and show up on the first day with a truck and directly unload into their pit.

[Toolbox crate, Will for Scale]

We often joke about how HyperShock is always built at the event. This is not wrong, but it also isn’t the whole story. We spend the off-season doing research and development. Where our schedule differs from most teams is we don’t commit to a design until we know how it's getting paid for. I talked about this in last week’s blog, this process of designing to the capabilities of sponsors. Since SendCutSend is providing us with a lot of direct services for sheet metal, we design a sheet metal robot. We can get away with this delayed commitment in part due to our history of delivering a working robot on time. We’ve run up to the wire many times, but we’ve never delayed our first fight.

[shop pit area]

We ship most of our tools and our hardware cabinet on the BattleBots ship day. We keep the handful of tools we need to finish the robot, but we have a lot of duplicates that live in our workshop. With how we’ve designed the robot this year, we had most of the modules built and ready before the chassis and armor parts arrived. With so little time to finish the robot, we rely on the design to handle all of the modules as intended. The other trick to all this is since most of our team isn’t local, it needs to all fly together in the hands of people who haven’t seen it before. We keep the non-local part of the team updated on the design and our progress, especially during the last few days.

[Checked baggage with group 1]

This year we received all of our armor and chassis parts just 4 days before flying to Las Vegas. It was a mad scramble to get armor panels bent and powder-coated. Alex and I flew out about 8 hours after the rest of the team so we could pick up the last of the powder-coated parts right before heading to the airport. I stuffed all of my clothes into one of the large pelican cases we use to transport armor panels so I could bring another case full of batteries as my carry-on. The FAA would probably like to ban lithium batteries from aircraft entirely, but so many devices use them that it just isn’t feasible. They have very strict limits on capacity per battery carried aboard, but no limit on the number of batteries below that capacity line. The logic being if one battery goes, it can be isolated from the other batteries. When flying with batteries, you should always bring a printout of the FAA restrictions and your airline’s restrictions on batteries. The TSA isn’t required to check your batteries, but they are likely to when you have a carry-on full of them. Their job is to ensure they’re safe, they may ask to check the capacities, but whether you can bring them aboard is ultimately up to the airline. You’re not required to declare that you have them, so it would be unusual for it to become a problem. The bulk of our difficulty usually lies in bringing more checked baggage than people, much of which is overweight or oversized. We try to determine the minimum number of bags that will need to be overweight, and maximize the weight we load into those bags.

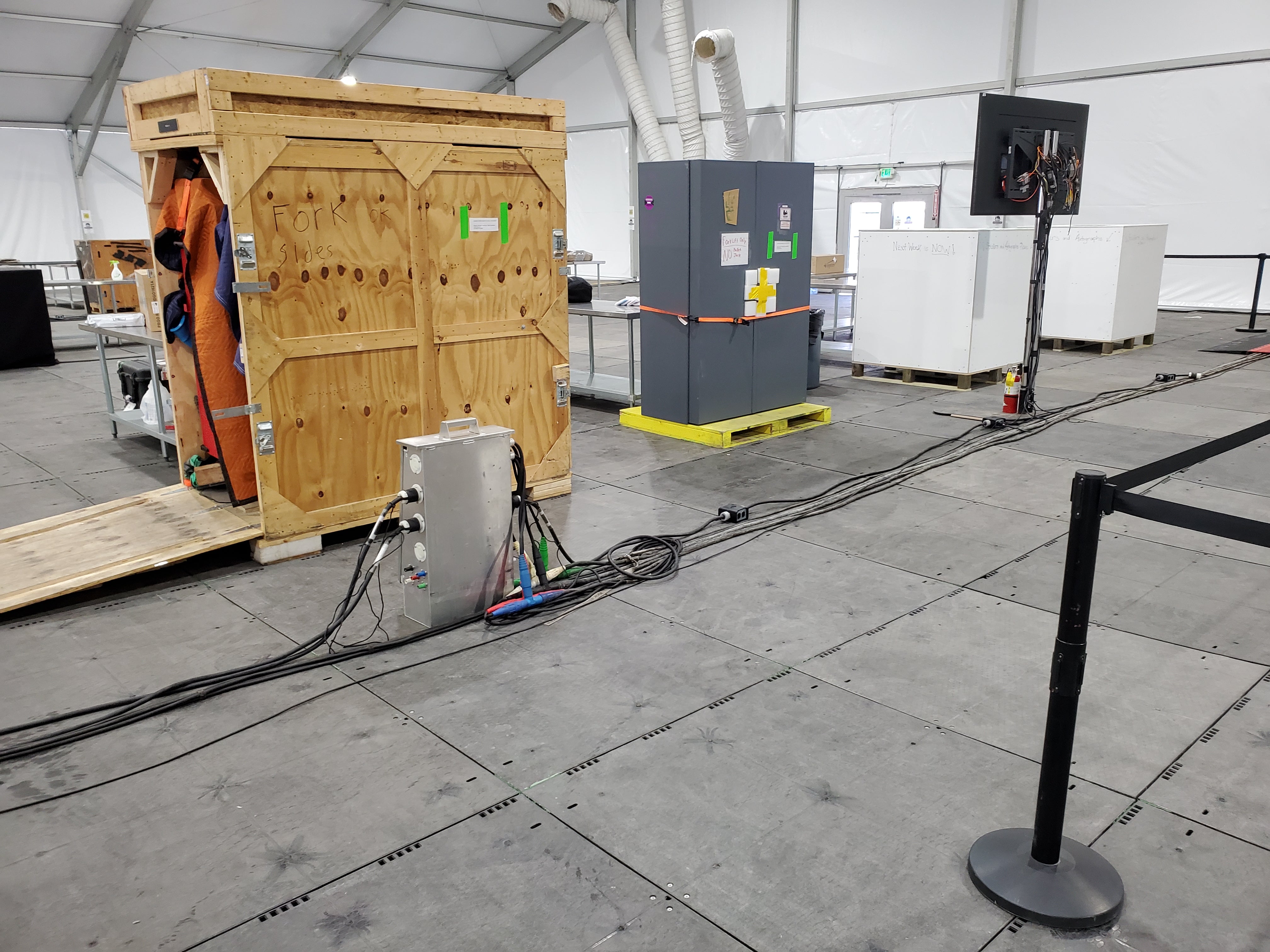

[Packed crates]

We bring about 4,000lbs of stuff to BattleBots. About 900lbs of it is three robots, another couple hundred pounds is made up of the large crate and cabinet. Hardware (screws, bearings, wire, etc.) is heavy. Especially when you need enough for three robots and then all the replacements. We have about 80 unique items on our hardware BOM. About 50 of those line items come from McMaster-Carr. We also ship a few sheets of metal and plastic in case we need to make something on site. Our toolbox is a little over 600lbs empty, and we load it up pretty well. We have an 8-foot tall wooden crate it rolls into along with some of our larger items like the neon sign. We also bring small creature comforts or acquire them while we’re there. Things like cushioned, rolling stools, and coolers for cold drinks can go a long way to reducing the stress of working 16 hour days.

[S6 pit area]

We plan out our pit layout in advance of getting to the venue. We’re given a pit map a few weeks out, but don’t know where we’ll be until we’re on-site. We come up with a few different possible layouts based on whether we’re in the middle of a row or on a corner. We leave some flexibility to accommodate how our neighbors are laying out their pits. Because the pits function as a filming location, we can’t have too many things taller than about chest height in the front half of the pit. Another reason why we go through all the trouble of making sure every single robot part is bright and identifiable: they make up much of the background of pit interviews. We added lighting to our hardware cabinet this year to help improve the vibrancy of the parts kept in there.

[pit tables]

We covered the tables in packing blankets to reduce the chance of damaging the paint or parts themselves. It’s also just nice to work on a cushioned surface. The pit tables aren’t well suited to being hammered on, so we started bringing our small table to BattleBots. We went so far as to drill holes in it to bolt a vise down. Having a secure vise in our pit is helpful. We use the space under the tables to store large items that we don’t need very often. Between people sitting and working at the tables, and the pit banner blocking the side of one, they’re somewhat inconvenient to get to. We set our pit up in such a way that there shouldn’t ever be anyone or a robot blocking access to the toolbox or hardware cabinet. We got lucky with our pit placement this year in that we didn’t have anyone behind us. Our soldering/electronics and art department ended up on a back table where they would be out of the direct line of sight. Those two stations tend to be the least visually appealing since half is covered in leftover vinyl and the other is mostly kept extremely empty so it's clear for soldering projects.

[Taking a lunch break]

We picked up an Adirondack chair on one of the trips to Home Depot. We also got a palm tree and an inflatable flamingo. We’ve found just a little bit of flair can go a long way towards making our pit a more fun place to be. We use our mostly empty, large wooden crate as a quiet space to make phone calls and set up a rack behind the hardware cabinet for jackets, backpacks, and other personal items. We also attached stick-on mirrors to the back of the hardware cabinet so we can fix our hair.

[Hardware Cabinet]

Our approach to storage is focused on primary access. We never want to have to do more than open a drawer to get to the thing we need. We use open-top, hanging bins to store all of our hardware so it's just a matter of reaching into the right bin to grab a screw. We’d previously tried using tip-out bins, but they’re just not large enough. They’re also much more expensive than hanging bins. Part of how we make this work is through hostility towards cardboard boxes. Everything from McMaster comes in boxes and bags, and sometimes further packaging. By immediately sorting items into our storage solutions, we ensure our system keeps running and we don’t get buried in cardboard.

[The shiny stuff on the floor is aluminum tape]

Season 6 had a fun bonus feature in the pits: the combination of super-dry desert air pushed through air-conditioners and an all-plastic floor meant static shocks were a constant irritant. They were also an existential threat to all of our electronics. There’s normally a pretty strict etiquette about not touching things in other teams’ pits, but especially this year with the risk of frying something expensive. It took a few days, but the builder community figured out we could use aluminum tape to build a conductive grid on the floor, helping us discharge ourselves passively. We had already planned to have a patch of vinyl flooring in the middle of our pit so screws dropped from the robots wouldn’t fall through the holes in the plastic floor panels. Turns out that worked great to help protect the robot from shocks. We took the conductive floor grid a step further by wearing conductive heel straps on our shoes to further improve the effectiveness.

Share:

Finances | How to spend all your money, your friends' money, and still end up broke.

Logistics 2 | A Day in the Life